Many times, local fire code requires that sprinklers be installed in your critical spaces. When water leaks are a concern, pre-action sprinklers offer a great alternative to regular water sprinklers.

Water-based fire sprinklers are designed to protect building structures—not your critical assets such as electronic equipment, data, or even collectibles and irreplaceable artifacts.

How is a Pre-Action Sprinkler System different from regular sprinklers?

Unlike regular sprinklers, pre-action sprinklers keep water out of your critical space with an automatically controlled valve. Only supervisory compressed air is inside the sprinkler pipe during normal operation. In the event of a leak in the piping network, compressed air—NOT WATER—escapes the pipe. The loss of compressed air will lower the air pressure in the pipe, causing a control panel to notify you of the trouble condition. We have put together information to assist you in: Understanding Pre-Action Systems

Water only flows to a sprinkler head when:

A smoke or heat detector exceeds a pre-determined level of alarm AND a sprinkler head melts due to fire

Advantage of Pre-Action Sprinklers

- Water does not flow if the sprinkler pipe breaks

- Water does not flow if a sprinkler head is damaged

- Water damage to your valuable assets is less likely to occur due to accidents or natural disasters such as an earthquake

Pre-action sprinklers are often used in conjunction with clean agent fire suppression systems. The clean agent fire suppression system acts as the first line of defense protecting your people, assets, and business continuity. Pre-action sprinklers meet minimum local fire code requirements and act as the second line of defense protecting your building structure.

Corrosion of Sprinkler Pipes

Microbiologically Influenced Corrosion (MIC)

•MIC inside of sprinkler pipe is caused by several different types of microorganisms.

•MIC combines with other elements to form tubercles and pits inside of sprinkler pipe.

•MIC has been discovered in Sprinkler Piping across the United States. Data Centers, Industrial Facilities, Warehouses, Hospitals, and Offices.

•MIC does not discriminate amongst fire sprinkler types. MIC exists in every type of sprinkler system.

Why does corrosion occur in sprinkler pipes?

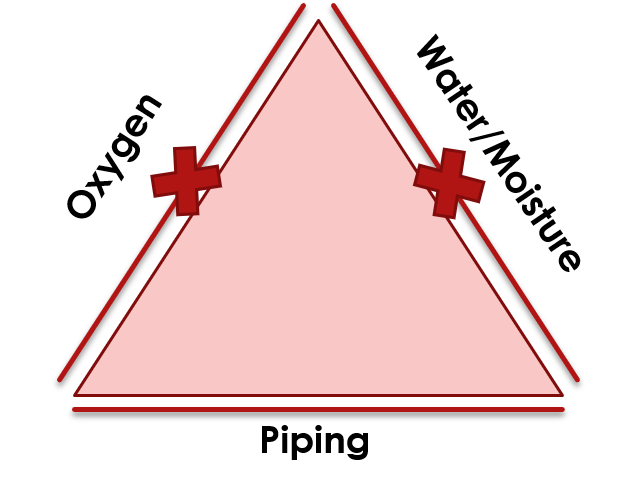

It is easily explained in the Corrosion Triangle below:

Oxygen + Water/Moisture + Piping = Corrosion

Oxidation Corrosion

- Corrosion is a major industry concern

- Efficiency of fire protection system heavily impacted

- System failure in a fire and/or ongoing costly repairs (leaks)

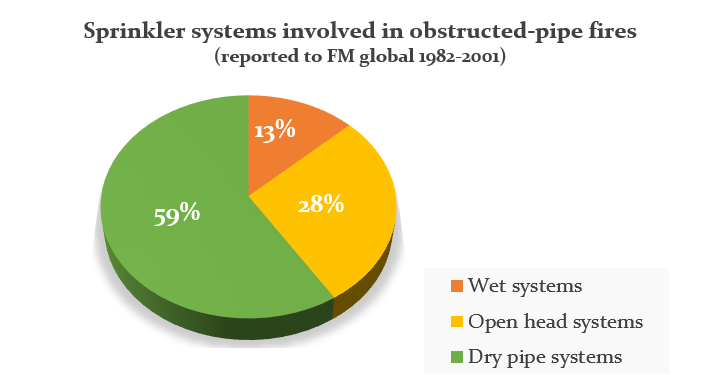

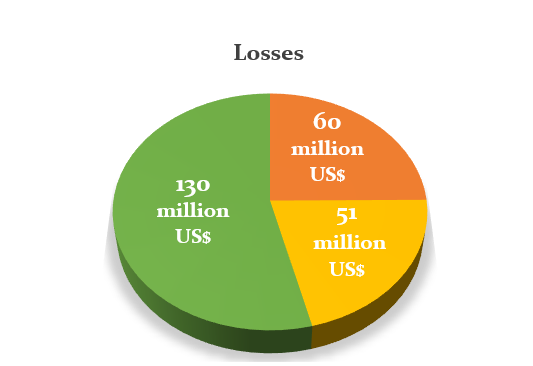

The corrosion effects many types of sprinkler systems and the losses from the systems not operating properly, have been in the millions.

Slime/sludge can restrict the flow of water in the sprinkler piping not allowing the sprinkler system to perform properly.

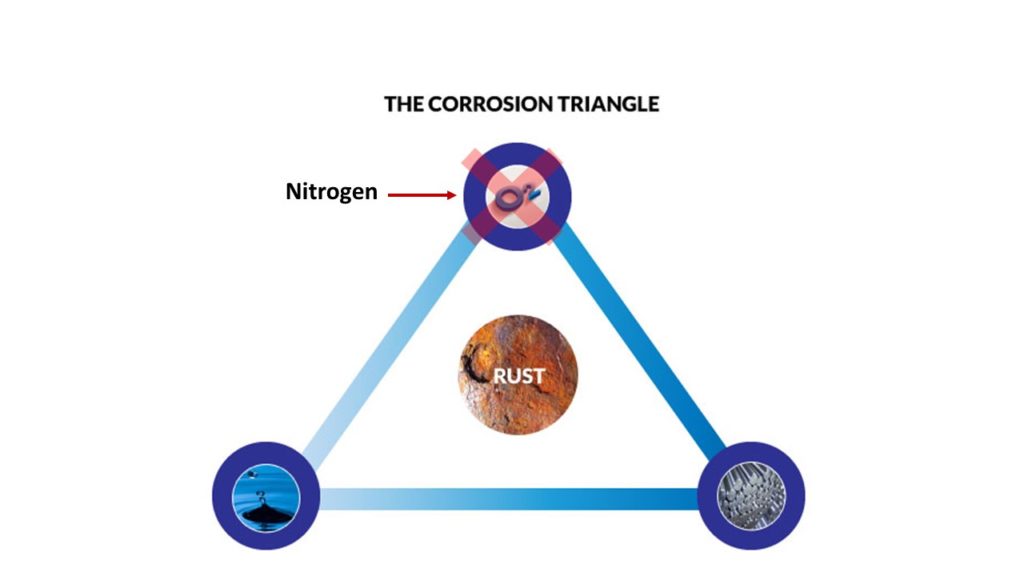

How do you stop the corrosion?

Replace supervisory compressed air with high purity, dry, supervisory nitrogen.

Industry Reports on Corrosion in Fire Sprinkler Systems

Nitrogen Inerting for Corrosion Control in Fire Sprinkler Systems by Engineered Corrosion Solutions. This document provides you with answers solutions for eliminating corrosion in fire sprinkler systems.

Nitrogen for Freeze Protection in Dry and Pre-action Sprinkler Systems by South-Tek systems. Dry and pre-action fire protection systems are vulnerable to the accumulation of condensate – and ensuing freeze-ups – as a result of inadequate sloping, failure to drain a system correctly, improper maintenance and lack of testing. However, even a well-designed fire protection system can collect moisture and potentially malfunction due to freezing.

Solutions

FireFlex TP3 N2 System

FireFlex TP3 N2 System is FM approved integrated Nitrogen System. Corrosion inhibiting system that limits the liability of early pipe replacement. All system electrical and mechanical components are contained in one single unit. Significant cost savings by using black pipe in combination of nitrogen.

Potter NGP-SPV – Nitrogen Self Purge Valve

The Potter Nitrogen Self Purge Valve (NGP-SPV) is designed to work with Potter Nitrogen Generators Systems to effectively purge corrosive oxygen from a fire sprinkler system while maintaining

adequate system pressure. Potter’s Self Purge Valve is the easiest way to ensure high purity nitrogen is equally distributed throughout the fire sprinkler system.

Control & Detection for Pre-Action System

Since our inception in 1990, Facilities Protection Systems (FPS) has made customer satisfaction our number one priority. Selecting the right solutions for your fire suppression needs is our specialty. FPS can furnish you with a complete fire suppression solution ranging from fire detection and controls to clean agent fire suppression and fire sprinklers.

Fire protection is important to your business. Finding the solutions to your fire protection needs is something we have been doing since 1990. Our customers have found that they can trust the experience, knowledge, honesty, integrity and ethics of our team. We invite you to contact one of the members of this team to discuss how we can protect your employee’s life safety and your valuable assets for the continued operation and success of your company. Contact us or call (714) 257-2244 for a Systems and Design Consultant to assist you with your needs.